- Need Free Consultation ?

Application

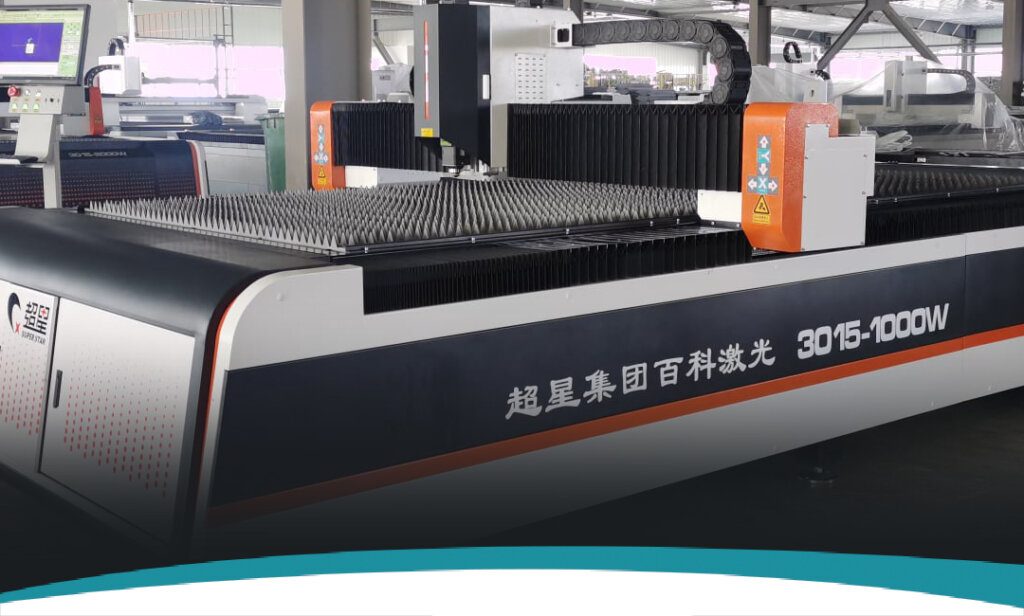

CNC Fiber Laser

Precision Cutting for Various Metals: Fiber Laser Cutting Equipment is specifically designed for precise metal cutting across a wide range of materials, including Stainless Steel, Mild Steel Plate (tube), Carbon Steel, Alloy Steel Plate, and Spring Steel.

Efficient Processing of Diverse Metals: This advanced equipment efficiently handles Iron Plate, Galvanized Iron, and Galvanized Sheet, ensuring clean and accurate cuts for various industrial applications.

Adaptable to Non-Ferrous Metals: The versatility of Fiber Laser Cutting Equipment extends to non-ferrous metals such as Aluminum Plate, Copper Sheet, Brass Sheet, and Bronze Plate, providing exceptional cutting quality for these materials.

Precise Work on Precious Metals: Whether working with Gold Plate, Silver Plate, or Titanium Plate, this equipment delivers precise and detailed cuts, making it ideal for applications requiring high accuracy and fine workmanship.

Comprehensive Metal Cutting Capabilities: Designed to cut both Metal Sheets and Metal Plates, this equipment is suitable for a wide array of metal types and thicknesses, providing flexibility for various cutting needs.

Tubes and Pipes Cutting: Fiber Laser Cutting Equipment is also highly effective for cutting Tubes and Pipes, offering precise and efficient processing for complex shapes and profiles.

Customizable Cutting Thickness: The cutting thickness can be easily adjusted based on the selected laser power, allowing for tailored solutions in sheet metal cutting, ensuring optimal performance for each specific project.

Enhance your metalworking operations with Fiber Laser Cutting Equipment, engineered for precision, versatility, and efficiency in every cut.